What makes for a good waterproof Tilebacker board?

10th April 2024

Marmox is renowned for its high performance building boards for tiling, dry lining, waterproofing and insulation, as well as floor level entry shower systems.

Mark Bowman, Technical Manager of Marmox UK Ltd, provides answers on how to select a waterproof backing board.

Question

The use of boards as a substrate for tiling is now common practice including so called waterproof tile backer boards. In a typical bathroom shower or wet room what are the essential properties required of boards suitable for tiling?

Answer

A wide range of boards are used within the UK building industry, ranging from timber based boards, gypsum plaster boards, cement boards and foam cored building boards. With specific reference to tiling, according to The Tile Association, there are just two boards and sheets that are suitable for all applications, whether they be internal, external, wet or dry environments. These two substrate materials are foam cored building boards and cement boards.

Cement based boards are strong and rigid making them ideal for tiling. In addition, they are resistant to mould and may be considered for internal and external applications. Although cement boards are not waterproof, they are water resistant. Consequently, whilst they do not entirely prevent the passage of water, they may be considered for wet environments. Cement boards are heavy sheets and may require two people to install. Their cementitious construction means that special carbide tipped tools and blades may be required for installation. In addition, cement boards are poor insulators, which may add to the risk of condensation.

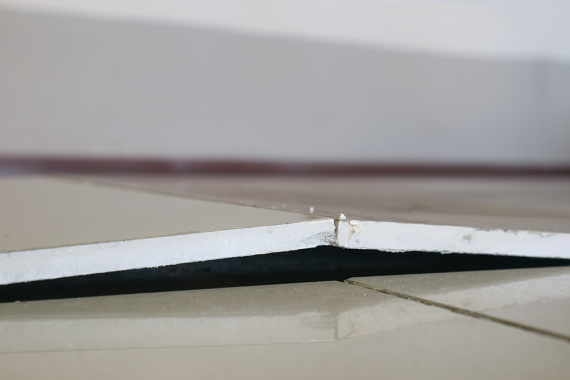

The most popular type of foam cored building boards are extruded polystyrene foam (XPS) core with reinforced cementitious layers bonded to the two largest surfaces. The XPS core is entirely waterproof and is therefore suitable within wet environments In addition, foam cored building boards are extremely lightweight, versatile, easy to cut and install, and have excellent insulating properties.

Question

What are the current building regulations or standards which relate to tiling to sheets and boards?

Answer

BS5385 is the code of practice for wall and floor tiling. According to BS5385, part 1, (2018) “the use of sheets or boards that are subject to movement from changes in moisture content, e.g. timber, should be avoided.” “Plywood and other wood-based boards should not be used for direct tiling.”

According to BS5385, part 3 (2018) “Timber sub-floors are not the ideal bases for floor tiling, especially where heavy static/dynamic loading is likely in service.” “If a timber sub-floor has to be used as a base for floor tiling, it should be rigid and stable with respect to humidity and moisture changes.”

In relation to wet, frequently damp, or high humidity areas, BS5385, part 3 (2018) states: “Timber is not a suitable base for floor tiling in wet, frequently damp, or high humidity areas unless appropriate precautions are taken.” “For tiling in frequently damp or high humidity areas, overlaying with appropriate lightweight tile backer board or uncoupling/tanking membrane is recommended.”

Essentially, the foam core of foam cored building boards is waterproof and an excellent insulator. Combined with the polymer modified cementitious layers this creates a rigid surface that is flat, watertight, and ready to tile.

Question

What additional factors need to be considered in relation to the movement created by expansion and contraction in floors?

Answer

Certain floors cannot be directly tiled because the lateral movement could result in cracked grout lines or even cracked tiles. A decoupling layer such as a foam-cored board allows such floors to be safely tiled. BSi recommend that a foam-cored board or decoupling membrane is placed on top of a timber floor prior to tiling in a damp area.

Question

How do these lightweight foam cored boards perform when compared to the strength of a heavier cement based board where the installation involves large format tiles or natural stone?

Answer

The maximum tiling weight is limited only by the capacity of the tile adhesive and the wall structure the board is fixed to. BS5385 provides guidance relating to the weight that can be hung from different substrate materials. For instance, BS5385 recommends that no more than 20 kg per square metre is hung from skimmed gypsum plaster and 32 kg per square metre from gypsum plaster board. However, if a skim of gypsum plaster is applied to plaster board, the weight limit is reduced from 32 kg to 20 kg per square metre.

Marmox developed Multiboard with its unique and patented textured concrete surface to provide a strong key, which means that when fixed with a continuous bed of adhesive, the adhesive itself will crumble before the bond between the board and the tiling would break, therefore the loading capacity typically far exceeds 100kg/m2.

Question

Many boards claim to be waterproof or water-resistant and suitable for wet areas. What is the difference?

Answer

Boards such as Gypsum Plaster Boards and Cement-Based Boards are water soluble and therefore cannot be referred to as waterproof. Foam cored boards such as Marmox Multiboard are water impermeable and the extruded polystyrene core is entirely waterproof and therefore provide the best choice for use in wet environments.

Question

Since many foam cored boards incorporate a reinforced cement based layer is it not true to say that they will absorb some water?

Answer

The rigid core of the Marmox Multiboard is fully waterproof and on both sides of the board is a fibre-reinforced coating of polymer modified concrete. This textured surface has been engineered to provide the ideal bonding conditions with tile adhesive as it offers the precise level of porosity and water absorbency needed to create the strongest bond. Installers choose Multiboard because it protects tiles from damage, and they can rest assured that tiles will not crack and will remain firmly bonded to the surface.