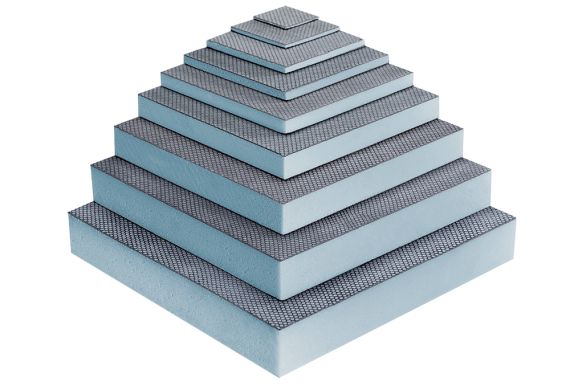

Marmox Multiboards are CE marked as rigid insulation panels. They provide a base for plastering on both internal walls and ceilings. As an alternative dry lining board, they provide thermal insulation and create a waterproof barrier.

Fix directly onto masonry walls, concrete, window reveals or onto battens. Marmox Multiboards offer durability and versatility, delivering professional-quality results every time.

Marmox Multiboards are composed of a unique blend of high-quality materials, with a honeycomb surface texture specially designed to optimise adhesion for plaster and tiles. This textured surface provides an ideal substrate for plaster application, ensuring superior bonding and a flawless finish. They are ‘pre-primed’ so once installed they can be plastered directly onto straight away.

Why Choose Multiboards for Plastering?

- Smooth Surface: Multiboards offer an ideal surface for plastering, preventing uneven walls and ceilings. They allow for professional-quality results that enhance the beauty of any interior.

- Durability: Crafted from high-quality materials and engineered for strength, Multiboards provide a robust foundation for plastering. Their resistance to moisture, mold, and impact ensures that your plastered surfaces remain pristine and intact for years to come.

- Ease of Application: Plastering onto Multiboards is easy, thanks to their lightweight and easy-to-handle nature. Achieve professional-quality results with minimal effort, saving time and labor costs on every project.

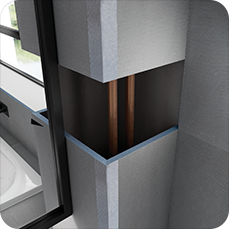

- Versatility: Whether you're plastering walls, ceilings, or even curved surfaces, Multiboards offer unmatched versatility. Their flexibility and adaptability make them suitable for a wide range of plastering applications, including curved walls, niches and pipe boxing, allowing you to bring your interior design visions to life.

Improving U Values

Marmox Multiboard is not only an excellent plastering substrate but also an all-in-one solution for internal wall insulation. With U value requirements varying across regions and building types, Multiboards significantly reduce heat loss through walls. For example, a typical solid wall with a U value of 2.1 Watts/m2K can be reduced by 70% to 0.60 Watts/m2K with a 40mm thick Marmox Multiboard.

Waterproof and Moisture-Resistant

One of the standout features of Marmox Multiboards is their waterproof nature, owing to their composition of Extruded Polystyrene (XPS). XPS is impervious to moisture, making it unaffected by wet conditions and ideal for areas prone to high humidity or water exposure. With no need for pre-treatment, you can plaster directly onto Multiboard, saving time and ensuring a hassle-free application process. Whether it's a bathroom, kitchen, or any other moisture-prone area, Marmox Multiboards offer peace of mind and long-lasting performance.

Marmox Multiboard, starting from 10mm thickness and above, proudly bears the CE mark, ensuring compliance with stringent criteria that demonstrate its efficacy in reducing heat loss through walls. Among the most sought-after thickness options for internal wall insulation are 20mm and 30mm, striking a balance between effective insulation and minimal space occupancy. For areas surrounding doors and windows, thinner boards such as 10mm or even 6mm can be employed to mitigate the risk of thermal bridging and condensation, providing tailored solutions for optimal thermal performance.

Applications of Multiboards in Plastering

- Interior Walls: Transform plain walls with Multiboards as your plastering substrate of choice. Achieve smooth, seamless finishes that enhance the aesthetics of any interior space, from living rooms and bedrooms to kitchens and bathrooms.

- Ceilings: Create stunning plastered ceilings that add visual interest and depth to your interiors. Multiboards provide a stable base for plaster application, ensuring uniform coverage and a polished, professional look.

- Feature Walls: Make a statement with plastered feature walls that serve as focal points in your home or commercial space. Multiboards offer the perfect canvas for creative plastering designs, allowing you to express your unique style and personality.

Experience Seamless Plastering with Marmox Multiboards

Unlock the full potential of your interior spaces with Marmox Multiboards as your plastering substrate of choice. Marmox Multiboards offer the perfect combination of smoothness, durability, and versatility for all your plastering needs.